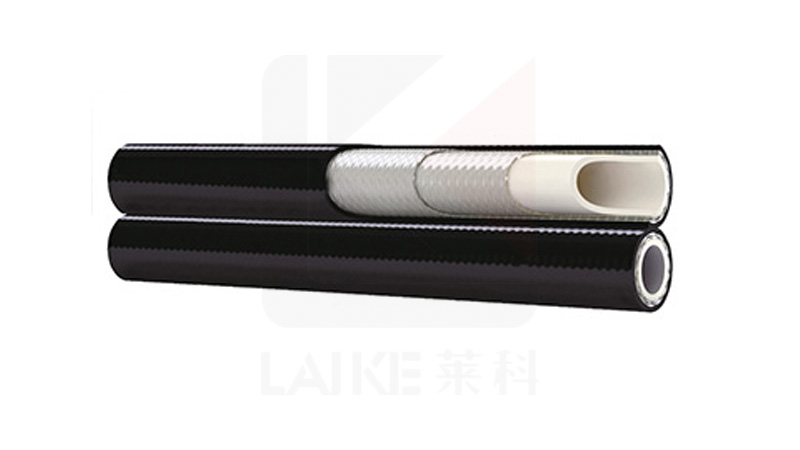

China Top Hydraulic Hose Manufacturer

With 30 Years Experience

Laike is a leading manufacturer of hydraulic hose fittings and hydraulic solutions provider in China. We have been focusing on the production of hydraulic products for more than 20 years, with complete quality control and rich product types, and a complete inventory can provide a complete one-stop service.

Request a Quote Today

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Submit Request

Best Hydraulic Fittings for Sale

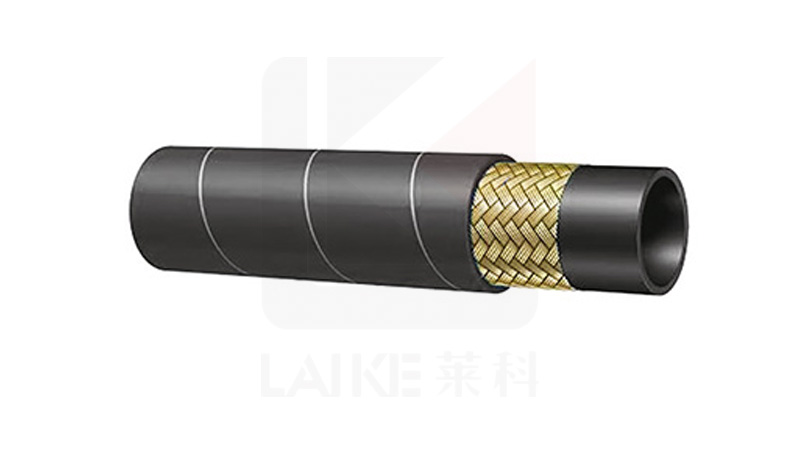

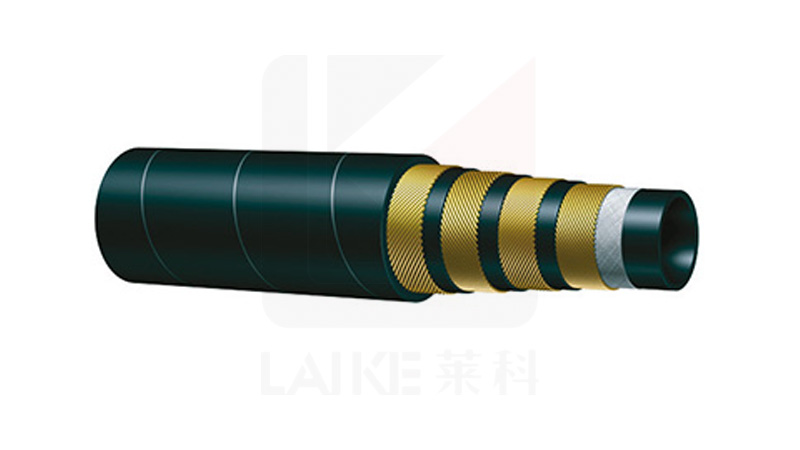

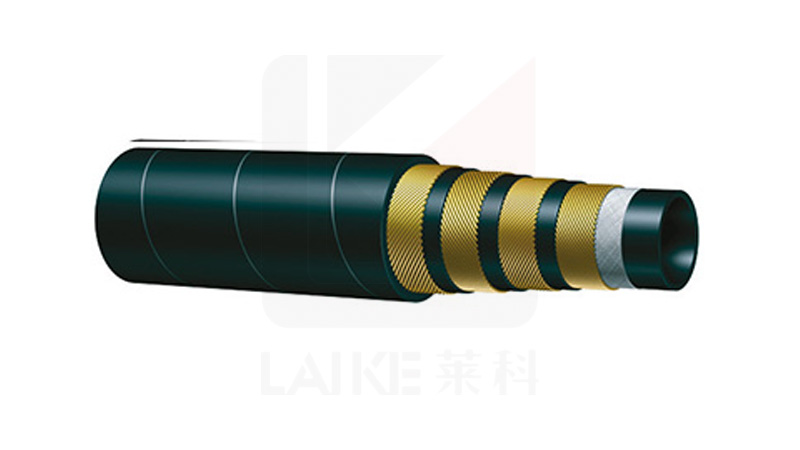

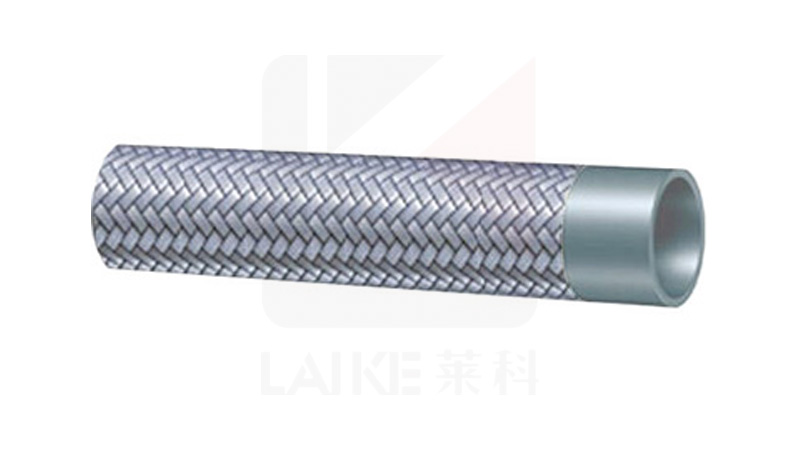

Laike is a manufacturer and supplier of Hydraulic Hose in China. Our products include various hydraulic connectors, adapters, quick connectors, crimping machines, hydraulic steel pipes.

We have our own hydraulic accessories factory and sales team. Years of production and sales experience enable us to provide complete one-stop service, fast response and perfect after-sales service.

If you have needs, please contact us immediately. We can provide fast response and free samples.

We have our own hydraulic accessories factory and sales team. Years of production and sales experience enable us to provide complete one-stop service, fast response and perfect after-sales service.

If you have needs, please contact us immediately. We can provide fast response and free samples.

Products

Why Choose Us

Competitive Price

Provide high quality Hydraulic Hose at a lower price

Production Capacity

Strong production capacity can quickly meet your needs

R&D Capabilities

The R&D team enables us to provide more updated products

Total Quality Control

Complete quality control process provides higher yield

Customer Approval

Years of production experience has been affirmed by customers

Fast Delivery

Foreign trade experience enables faster delivery

Request a Quote Today

Factory Tour

Laike is a manufacturer and supplier of Hydraulic Hose in China. We have our own factory and foreign trade department, if you have needs, please contact us immediately.

Buy FAQ

1

Are you a factory/manufacturer or a trading company/trader?

Yes, we have our own factory, located in Ningbo City, Zhejiang Province. If you want to visit our factory, please contact us in advance and we will arrange a trip for you.

2

Can I request a sample?

Yes, we offer free samples. But you need to pay for shipping by yourself.

3

How long is the delivery time?

Normally, about 45-60 working days. Orders with multiple parts/custom products will take longer. We have a certain amount of inventory, which can completely deal with small batch shipments.

4

What is your payment term?

T/T 30% deposit, balance paid before shipment.

5

What is your MOQ?

$15,000 per order, or an additional $350 handling fee under $15,000.

6

Do you accept OEM/ODM?

Yes. We are a professional manufacturer of hydraulic pipe fittings with rich experience in the manufacture and design of hydraulic products. With a professional technical team, we can digest OEM/ODM orders.

7

What is your shelf life service?

Replace or refund defective products.

8

Can we be your reseller?

We sincerely invite your business to join our success. If you are interested in cooperation, please contact us directly.

9

Why Choose Laike

· Laike has successively obtained ISO9001:2000, RoHS and other certificates, joined CHPSA, served as the trustee of NHPSA, applied for and obtained the American LAIKE trademark, etc.

· The production equipment used by Laike is advanced and complete to ensure reliable guarantee of product output.

· With a professional technical team, product design and production are reliable and efficient. Our technical staff have won numerous awards in skill competitions.

· With reliable quality, reasonable price and excellent service, we have successfully established our reputation and won customers from all over the world. Some of our major customers include Parker, Eaton, Terex, PrincessAuto, etc.

· Our cooperation includes OEM/ODM services, customization, etc. We will strive to keep up with our work, upgrade and improve, innovate and invent, thereby strengthening the partnership with customers.

· The production equipment used by Laike is advanced and complete to ensure reliable guarantee of product output.

· With a professional technical team, product design and production are reliable and efficient. Our technical staff have won numerous awards in skill competitions.

· With reliable quality, reasonable price and excellent service, we have successfully established our reputation and won customers from all over the world. Some of our major customers include Parker, Eaton, Terex, PrincessAuto, etc.

· Our cooperation includes OEM/ODM services, customization, etc. We will strive to keep up with our work, upgrade and improve, innovate and invent, thereby strengthening the partnership with customers.

Choose the Best Hydraulic Hose Manufacturer

Laike Hydraulics is committed to developing and manufacturing hose fittings, hydraulic adapters, hose assemblies and other related products that are widely used in mining, machinery, transportation, shipping, and oil fields. With more than 20 years of learning, growing and development, we now own plant of 18,000 square meters, machines of 200 sets, employees of 100 and store regularly used items of 40,000 kinds.

It is the long-standing commitment to “first class design, first class products, first class service”that has made Laike Hydraulics a name synonymous with hydraulic fittings and adapters. We sincerely welcome everyone from worldwide to visit us.

Read More

Contact Now

Submit Request